The point where the rubber bands are fastened to a slingshot is vital in several ways. First, its failure can lead to a band snapping back into your face. Second, it undue stress at this place has a severe impact on the lifespan of your rubber bands. Third, bulky attachments can obstruct the view on the target. Choose an attachment method that is tender to the bands and doens't clutter picture.

Works with: Every kind of rubber, especially flat bands

Advantages: Flexible, force is spread overy a broad area, not much force on attachment point itself

Disadvantages: Fork ends must be well-made and smooth

The "over the top" method is executed by fastening the rubber bands to the front side of the fork ends, and let them run over the (well rounded and sanded) top of the slingshot. This attachment is by far the most common in the Western World, and with reason. It looks elegant, is tender to the rubber and the bands form a sharp line when the slinghot is held sideways, thus giving the shooter a precise feedback if he holds the slingshot at the correct angle. The fork tip with its sharp 90° angle at the side is a good reference point for aiming. Disadvantage is that a beginner who is unfamiliar to this method can take the slingshot the wrong way and pull the bands out of the attachment, which results in a slap to the face. Other than that, it is highly recommended, especially for flat bands.

Works with: Cubic, tubular and flat bands

Doesn't work well with: Very broad flatbands

Advantages: Flexible, bands only get in contact with leather loop.

The "Spain style" attachment relies on a piece of string or leather that is fastened to the fork ends and form a flexible attachment point for the bands. There are many different versions of this design. The bands don't touch the frame during the shot if this method is done correctly, this increases their lifespan.

Works with: Double or quadruple cubic and tubular bands

Doesn't work well with: Broad flatbands, single bands

Advantages: Flexible, force is spread over the whole front area

Disadvantages: Only works with dual / quadruple bands, relatively complicated bending is necessary

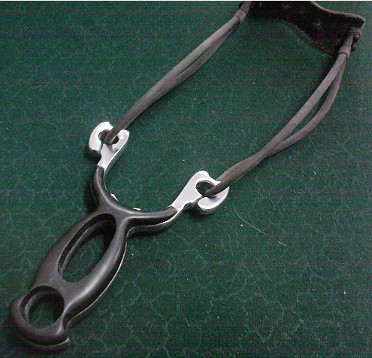

The Chinese attachment method consists of a loop at the fork ends that hold the bands, which are attached

to the pouch with both ends. Chinese slingshot shooters almost exclusively use this kind of attachment,

and regard it as the best method. And indeed, it is a perfect match for the small-diameter

latex tubing that is the dominant band material in China. The bands can be changed in seconds, if the loop

has a small slit that allows the bands to slide in when pulled taut. The Chinese attachment is tender on the bands and

can provide you

with a very precise sight picture when you hold the slingshot horizontally, as the small opening between the

bands gives you a feedback on the slingshot's alignement, and prevents target obstructions by the bands.

Disadvantage of the Chinese attachment is its inability to define the band length while attaching them. This

raises the need for precisely made bandsets with the same band length on each side, and is problematic when

trying to recycle worn-out bands by re-attaching the pouch after cutting away the broken band end.

Works with: Every band type

Advantages: Very simple to make, not much carving work necessary

Disadvantages: Bands must be tied down well, fork end can obstruct target

One of the most underrated methods are the "African style" and the "Tie-down".

They work by simply tying the bands towards the backside of the fork, using sufficient

rubber to secure them in place. The bands will either run downwards to the attachment -

this is nice if you want to hand the slingshot around your neck - or will run upwards towards

the fork ends, which makes them fold up nicely along the frame while you keep the slingshot in the

pocket.There is no need to prepare the forks, so these attachment methods are great for crafting

a slingshot in short time and with limited tools. However, be aware of its limitations. The

rubber you use to tie down the bands must be strong enough to keep everything in place. It is easy with light bands, but

becomes an issue when you intend to make a slingshot with a high drawing weight.

I recommend to fold the band ends back into the attachment zone, as this lessens the chance of a pull-out.

A carved groove in the fork also increases safety. You can go 100% safe by using one big rubber loop instead of

the two bands you'd normally have, and tie it down all the way from one fork end to the other.

If everything is done well - and it must be done well, unless you

want a band in your face - you get an attachment that is very similar to the "Over the Top" method, only

that you pull the bands against the rubber and not against the fork ends.

The "African style" method is also a good way to retrofit mass produced bent-wire slingshots

with flatbands.

Works with tubes only

Advantage: Easy to make commercially.

Disadvantages: More complicated than it looks, not flexible, needs band protectors / rotating prongs to work well

This is by far the most common method employed in mass produced slingshots. You can simply push an alcohol-moistened tube on the end of a steel or plastic rod, the bands will stay in place after drying. The diameter of the fork end must be at least 150% of the inner diameter of the rubber tube - for example, a 6mm fork end can accomodate tubing with 4mm inner diameter. This attachment can be made in an automated process, which makes it so attractive for mass production. It looks like a clean, simple way to secure the bands - but don't be fooled by it: The fork ends wil kill your bands in short time umless they are very carefully rounded and polished. And even then, they are harsh to the bands. Manufacturers try to make things better by adding plastic tip protectors, polishing the ends, adding protective sleeves or -the best way- make the prongs rotating. The better commercial models are quite succesful with this attachment method but there is, in my opinion, no reason to choose it for a homemade slingshot.

Works with: not-too broad flatbands, also tubes (depends on slot size etc)

Advantages: Very easy to adjust band length or change bands

Disadvantages: Fork ends often obstruct the view to the target, not flexible in horizontal plane, shooters often experience shifting bands, slots must be rounded well

Cut two narrow slots inside the fork end. They must be half as thin as the band is. Then, grind away the sharp edges, and be sure that the wood is strong enough to withstand the pulling force. This method keeps the bands parallel to each other, and is quite popular for flat bands. Disadvantage is that the rubber inside the slot may slowly move upwards with each shot, and the slot size limits you to specific bands: Too slim and they slip out, too big and they don't fit in.

Works with: not-too broad flatbands

Advantages: Very easy to adjust band length or change bands, bands

Disadvantages: Fork ends often obstruct the view to the target, not flexible in horizontal plane, shooters often experience shifting bands, slots must be rounded well

This method was used on famous slingshots like the Tinker Killdeer or the Scopeshot. Cut a slot in the middle of the fork. It should be about 2mm deeper than the rubber is broad, and shall be as wide as the rubber is. Grind away the edges to make the bands last longer. Then, take a rubber, fold back about 2cm and insert a small piece of wood (a matchstick, for example) in the loop. The piece of wood should be at least as strong as the slit is wide! Then, extend the rubber af far as you can and insert it into the slot. It is a nice method - really easy to make, very reliable, the bands are always 90 degrees to the shooting axis (making the shot more powerful and accurate) and replacing the rubber is done in seconds. Disadvantage is that the rubber inside the slot may slowly move upwards with each shot, and the slot size limits you to specific bands: Too slim and they slip out, too big and they don't fit in.

Works with: Any kind of band

Advantages: Very easy to adjust band length or change bands

Disadvantages: Works only with certain types slingshots (e.g. models made of flat steel)

Another excellent way, if the slingshot material permits to employ it: Simply squeeze the end of the bands between two fork end parts, by means of two screws. Cushioning with leather or rubber enhances band life. It is simple, secure, the bands are straight and can be changed in seconds. Both tubular and flat bands can be attached this way.

Works with: Tubes

Advantages: Very compact, easy to change bandlength, bands stand straight back (good for fast reloading)

Disadvantages: Dangerous! Risk of severe injuries if things go wrong. Use with caution. Only for metal slingshots. Requires carful drilling and sanding.

It is possible to attach tubular rubber to a slingshot by pushing the bands through a hole in the end of the fork and insert something (usually a metal bb) into the tubes. It looks neat and doesn't need much space on the fork end, which makes it popular on small pocket slingshots. Saw very thin slots from the edge to the holes in the fork end and you can insert pre-made band assemblies in a few seconds by pulling the bands taut and inserting then through the slots. It is a good idea to countersink the hole fron the front side, this lets the BB sink a bit deeper into the slingshot's frame and decreases the chance that the bands slip out of the slot.

This method works well, but has some grave disadvantages: First, the holes need to be well rounded and polished to keep the bands intact. Second - and most important - the bands will fly straight to your face with an inserted BB if the fork ends break or the bands manage to slip through the hole or the slot. Daisy Mfg. had to start a big recall of slingshots using this type of attachment because the attachment failed and led to several severe injuries.

So I don't recommend this method, unless you really know what you are doing, and trust the material your slingshot is made of. Always take a BB with a larger diameter than that of the holes.